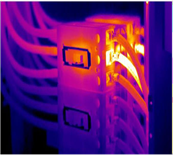

Infrared Thermography

Electrical equipment can fail due to corrosion or loose connections within the equipment. Equipment failure is not only costly to your business, but it is dangerous for your employees. By using Infrared Thermography to locate hot-spots within your equipment, you can identify these potential problems before they occur. These assessments will show you where minor repairs are needed and the urgency at which to repair before it leads to catastrophic breakdown. Repairs after a thermographic inspection are lower in cost and can be done on your time.

Turn Key Project Process

|

Scanning will be done for each and every feeder connections, breaker and bus bars. |

Reports will be given and explained to the team where the system will face faults. |

Training to the operators on corrective measures required |